Order processing includes picking the item(s), quality inspection, packaging and labeling, and dispatching. Managing inventory means receiving and recording the goods, monitoring stock levels, and otherwise organizing and accounting for it all. Failure to manage inventory means stock-outs, damaged goods, and waste. Moreover, the cost of managing inventory does not end with renting space and hiring staff. It also includes administrative, technology, and overhead, such as insurance.

Expansion involves:

- Quality control for packing, presentation, shipping, surprises.

- Elevated customer experiences for speed, communication, support.

- Branding and materials for customized packaging.

- Better control over inventory levels, avoiding stock-outs.

- No barriers between you and the customer.

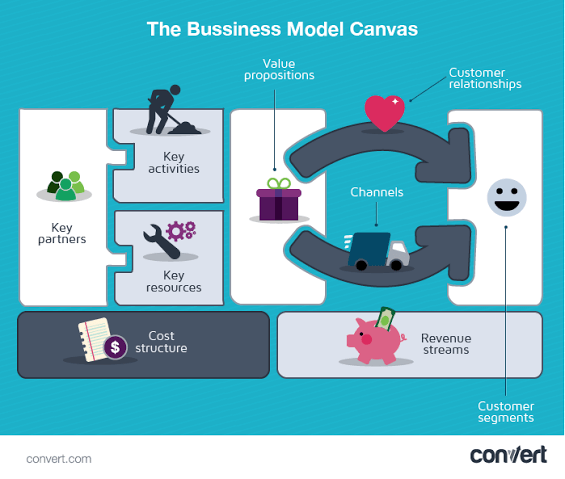

There are four main cost centers for in-house fulfillment: warehousing, labor, packaging materials, and shipping. Shipping will likely be outsourced unless deliveries are local with your own transport.

- Startups.

- Order volumes of less than 20 per day.

- Customized orders or unique customer requirements.

- New product lines and suppliers.

- Alternative picking and packaging processes.

- Local customers.

- Existing capacity (warehouse and employees).

- Adequate funding to invest in technology.

What’s Involved?

There may also be an on-boarding fee. Remember to add shipping when comparing the total cost per order. An outsourced provider could likely offer lower shipping costs due to volume discounts it receives from carriers.

In-house fulfillment is best suited for one or more of the following:

- Locating and securing suitable warehouse space. Consider starting with a secure storage unit or space in an existing facility. Try to allow for flexibility if growth is faster or slower than anticipated

- Employ and train staff.

- Research and source equipment and software for packing and labeling and, potentially, for automation.

Here is a hypothetical framework of how to estimate potential fulfillment costs.

- Loads new orders automatically from your ecommerce platform but also allows for manual order entry and editing.

- Tracks inventory movements in and out and alerts for low stock levels.

- Integrates with your existing software — accounting, customer management, ecommerce.

- Processes product returns and credit notes

- Runs reports on demand

- Tracks historical volume to anticipate staffing needs and stock on hand.

Costs

Many emerging ecommerce businesses start in someone’s garage or kitchen. They store, pack, and ship from a home base and control all the activities. But even established sellers sometimes opt for fulfilling in-house.

The benefits include: Automation of routine tasks expedites and synchronizes the order fulfillment process. Select a software provider for only the functions that you need. Look for software that:

- Receiving of inbound inventory, per hour of labor.

- Storage, usually either by pallet or bin, per week or month.

- Picking, packing, and labeling (per item).

- Special services, including returns handling.

By estimating the average fulfillment cost per order (.80 in our hypothetical example), merchants can compare to outsourced providers and decide on the best option for their business. There is no standard pricing for third-party fulfillment, but costs will likely include a monthly management fee plus charges for:

![The Amazon Seller Fulfilled Prime Guide [How Will 2021 Changes Impact Sellers?]](https://research-institute.org/wp-content/uploads/2021/04/what-to-know-before-you-sell-your-small-business-768x432.png)